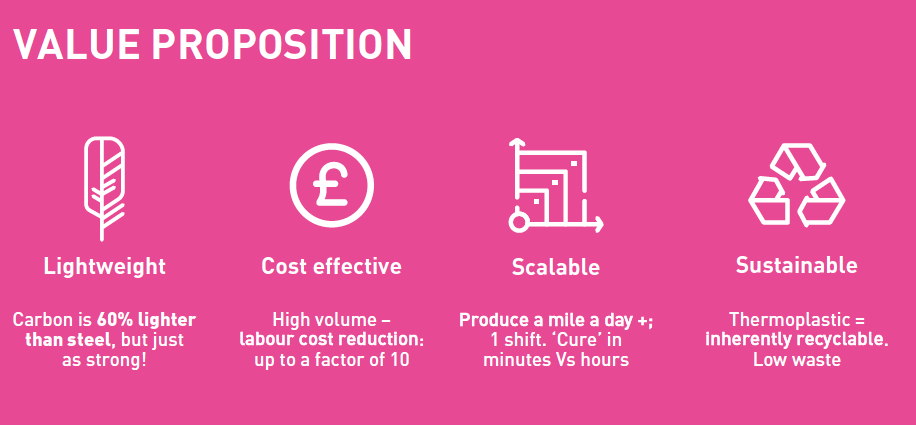

Our company’s value proposition has four key aspects and sustainability is one of them. But what does this really mean in practice?

Put simply, it’s about helping people make products that have a lower carbon footprint. Our technology and expertise can contribute to your de-carbonisation plans and net zero carbon targets. How?

Products that are inherently recyclable

The thermoplastic matrices we use in our manufacturing process are inherently recyclable, because thermoplastics can be reshaped again and again using only heat and pressure — there is no need for harmful chemicals. Traditional thermoset composites can’t be remoulded and are more difficult to recycle. Our materials are much easier to re-use, re-purpose and if need be, recycle.

Lighter components

The components we produce are lightweight — typically 60% lighter than steel for the same strength and stiffness. When used in vehicles, they reduce emissions, increase range and reduce energy usage. When used in infrastructure, they reduce energy requirements for installation as well as for servicing throughout the life of the product.

Low waste process

Our manufacturing process reduces waste by up to 95% compared with traditional composites manufacturing. Here’s why:

- The braiding process itself is very high yield, with little to no set-up wastage

- Leftover material can usually be reused in subsequent jobs

- There is also near-zero waste from the final, consolidation process.

Low energy process

With world-beating lightweight tooling and high-speed heating technology in development, we are continuing to reduce our carbon footprint. Lighter tools can be created and delivered using fewer raw materials and less energy. By combining fast heating with lightweight tooling, we also use less energy when producing your finished goods.

We want to do more

However, we know that there’s more to be done. That’s why we’re working with the High Value Manufacturing Catapults set up by the UK Government, and others, to make composites more sustainable. Specifically, we’re part of the ReDisCoveR Composites project, which is looking at Recycling, Disassembly, Circular Materials, and Reuse in composite manufacturing, and the Composites UK Sustainability Sub-Group.

Find out more

We’d love to talk more about how our composite manufacturing technology can help to de-carbonise your processes. Contact us and let’s start a conversation.